Datasheet 搜索 > 开发套件 > Maxim Integrated(美信) > MAX31855PMB1# 数据手册 > MAX31855PMB1# 开发手册 1/7 页

¥ 252.942

MAX31855PMB1# 开发手册 - Maxim Integrated(美信)

制造商:

Maxim Integrated(美信)

分类:

开发套件

描述:

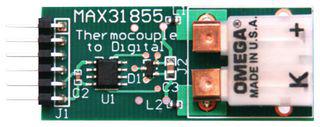

评估模块, MAX31855 K型热电偶至数字转换器, 14位输出

Pictures:

3D模型

符号图

焊盘图

引脚图

产品图

MAX31855PMB1#数据手册

Page:

of 7 Go

若手册格式错乱,请下载阅览PDF原文件

Maxim > Design Support > Technical Documents > Application Notes > A/D and D/A Conversion/Sampling Circuits > APP 5758

Maxim > Design Support > Technical Documents > Application Notes > Embedded Security > APP 5758

Maxim > Design Support > Technical Documents > Application Notes > Interface Circuits > APP 5758

Keywords: analog integration, integrated factory, hardware-based security

APPLICATION NOTE 5758

Analog Integration Drives Factory Integration

By:

John Mossman, Control & Automation Marketing

Manager

Mar 21, 2014

Abstract:

Analog integration is driving the integrated factory. Advances in analog and mixed-signal ICs contribute greatly to

factory productivity, efficiency, quality, safety, and security. These all lead to increased uptime and reduced maintenance costs.

This integration enables robust machine to machine (M2M) communications and ultimately the internet of things (IoT).

Distributed intelligence, smart machines, smart sensors, and the integration of factory data with business-management systems

(information technology or IT) allows optimization of not only the factory process, but also material handling, machine utilization,

scheduling, reporting, and throughput.

A similar version appears on EDN, December 7, 2013.

Introduction

Advances in analog and mixed-signal ICs have contributed greatly to unprecedented combinations of factory productivity,

efficiency, quality, and safety. These ICs enable higher system performance, increasingly accurate measurements, robust

communication, lower power, and higher levels of security. They are central to factory systems that act rapidly on large numbers

of sensor-based measurements that precisely control material handling, processing steps, power and temperature, and

operational safety.

When computational resources are integrated into these analog and mixed-signal ICs, the factory can deploy a distributed

intelligence model. Factory data can now interface more readily with business-management systems. This integrated factory

model, comprising many of the techniques and technologies described below, makes factory information available worldwide in

real time to supply chain, sales, logistics, and senior management.

Distributed Intelligence

Integrated factories exploit distributed intelligence, pushing computational resources and decision making out of the control

room and into widely dispersed process machinery. This shift in system architecture delivers data to management personnel in

almost real time. It eliminates data-processing bottlenecks. It allows management to deploy more measurement and control

nodes, and to act on significantly larger sets of process data.

The benefits of distributed intelligence to the factory floor can actually be summarized in a single concept: uptime. Factories will

reduce measurement-to-control feedback latencies; experience better reporting of process efficiency, throughput, WIP (work-in-

progress) status, and machine utilization; and lower maintenance costs.

Benefits to the company, however, extend far beyond the factory floor. Integrated-factory systems provide up-to-the-minute

workflow data, which, when combined with supply-chain intelligence, allow operations to optimize their scheduling and inventory

management. Worldwide sales and distribution management can act on precise and timely factory productivity data.

Management can better optimize production-line balancing and capacity utilization.

These many benefits clearly depend on sophisticated software tools for optimal operation at the highest level of abstraction. But

Page 1 of 7

器件 Datasheet 文档搜索

AiEMA 数据库涵盖高达 72,405,303 个元件的数据手册,每天更新 5,000 多个 PDF 文件