Datasheet 搜索 > RF射频器件 > ADI(亚德诺) > ADF7020-1BCPZ 数据手册 > ADF7020-1BCPZ 产品封装文件 1/2 页

器件3D模型

器件3D模型¥ 0.31

ADF7020-1BCPZ 产品封装文件 - ADI(亚德诺)

制造商:

ADI(亚德诺)

分类:

RF射频器件

封装:

LFCSP-48

描述:

ANALOG DEVICES ADF7020-1BCPZ 芯片, 收发器 ISM频段

Pictures:

3D模型

符号图

焊盘图

引脚图

产品图

页面导航:

功能描述在P1

导航目录

ADF7020-1BCPZ数据手册

Page:

of 2 Go

若手册格式错乱,请下载阅览PDF原文件

AN-1389

APPLICATION NOTE

One Technology Way • P. O. Box 9106 • Norwood, MA 02062-9106, U.S.A. • Te l: 781.329.4700 • Fax: 781.461.3113 • www.analog.com

Recommended Rework Procedure for the Lead Frame Chip Scale Package (LFCSP)

by Ramon Navarro

Rev. 0 | Page 1 of 2

INTRODUCTION

This application note provides a recommended procedure for

removing the lead frame chip scale package (LFCSP) from the

printed circuit board (PCB). The LFCSP is compliant with the

JEDEC MO-220 and MO-229 outlines. This application note is

supplementary to the AN-772 Application Note, A Design and

Manufacturing Guide for the Lead Frame Chip Scale Package

(LFCSP).

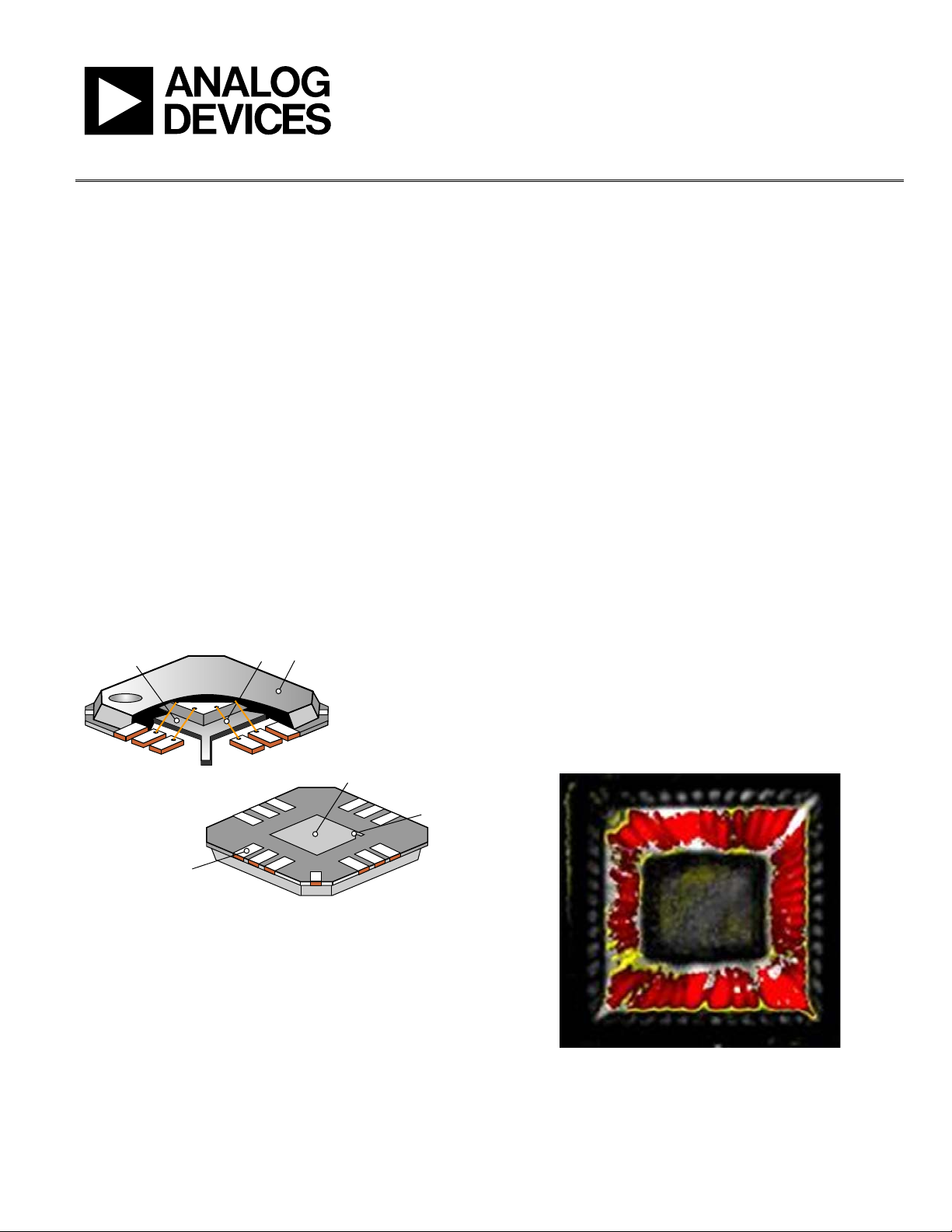

PACKAGE DESCRIPTION

The LFCSP is a plastic encapsulated package that is lead frame

based and has a footprint close in size to the chip or die, thus

being chip scale (see Figure 1). Interconnection inside the

package is typically achieved through wire bonding.

Make external electrical connections by soldering the perimeter

leads to the PCB. In addition to the leads, the LFCSP commonly

has a large exposed thermal paddle, which can be soldered to

the PCB for improved heat dissipation.

DIE PAD

GOLD

WIRE

MOLDING

COMPOUND

EXPOSED

THERMAL PADDLE

PIN 1

PERIMETER

INPUT/OUTPUT PADS

(LEADS)

13856-001

Figure 1. Isometric, Cut Away View of the LFCSP

REWORK FOR LFCSP COMPONENTS

If defects are present after attaching the LFCSP component to

the PCB, rework to remove the defective component and replace

it with a functioning device. Before removing the device, note

that the defective component must be heated until the solder

underneath the leads and the exposed thermal paddle (if

soldered as well) is liquefied, which makes removing the

component from the board easier.

The conventional rework process includes the following:

1. Board preparation

2. Component removal

3. PCB land clean up

4. Application of the solder paste

5. Component alignment and placement

6. Component attachment

7. Inspection of rework

See the AN-772 Application Note for a more detailed

description of Step 3 to Step 7.

COMPONENT REMOVAL AND DELAMINATION

The manner of component removal can impart mechanical

stress on the LFCSP and/or the PCB. Remove the defective

device carefully to avoid damage not only to the PCB or nearby

components but also to the device itself, particularly if a user

plans to subject it to failure analysis. Excessive stresses on the

LFCSP component (such as heating the component beyond the

specified peak temperature or overexposure to heat) can lead to

package delamination or external physical damage (see Figure 2

to Figure 4). For a component that must undergo further

analysis, delamination caused by improper component removal

makes identifying the true failure mechanism more difficult.

Consequently, proper removal of the defective component is

necessary to conduct effective failure analysis.

13856-002

Figure 2. LFCSP Die Pad Delamination Due to Improper Removal (Observed

Through Scanning Acoustic Microscopy)

器件 Datasheet 文档搜索

AiEMA 数据库涵盖高达 72,405,303 个元件的数据手册,每天更新 5,000 多个 PDF 文件